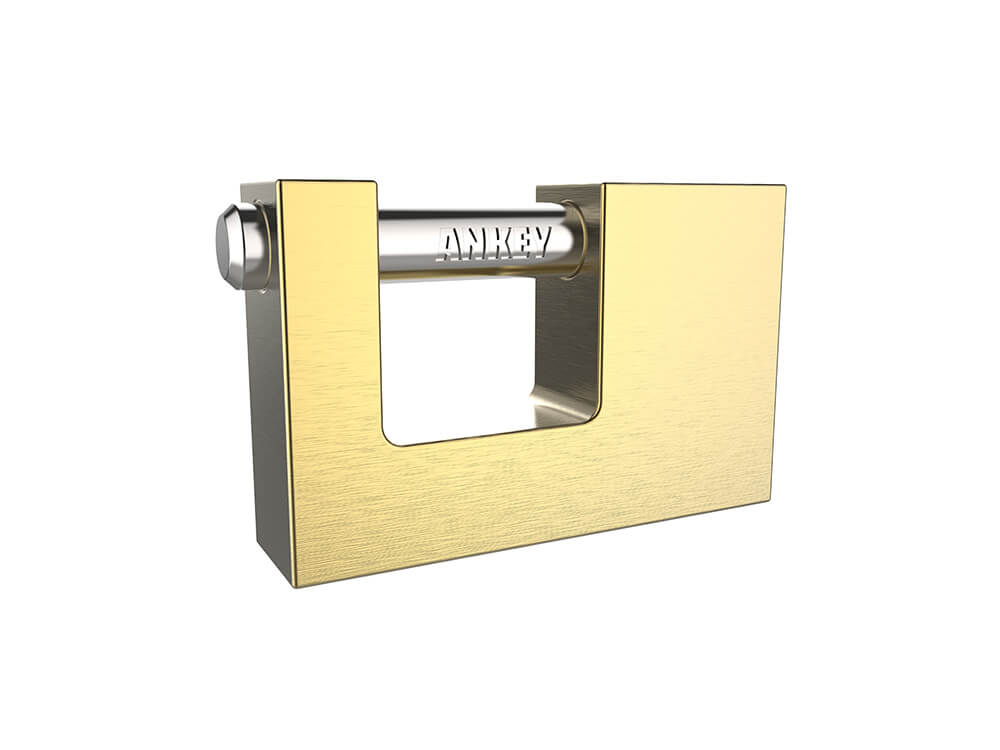

Laminated Padlock

Laminated Steel padlock PL0028

>Cut resistance

>Superior strength

>Rust proofing

>Key differ

>Keyed alike

Highlights

Laminated Steel padlock PL0028

Laminated Steel padlock PL0028

Size available in 30mm, 40mm, 50mm, 60mm

Standard iron shackle chrome plated

Laminated steel body for superior strength

Iron cylinder or Brass cylinder

2pcs or 3pcs keys in iron/brass material

Best Manufacturer

Ranked top 10 of iron padlock manufacturer in China that ensures stable quality and on time delivery.

Competitive Price

Laminated steel padlock always in the range of economic consideration to bring one lock to you for durable use.

Quality Control

Third-part inspection involve & Package Control system at Ankey keep the lowest complain about quality issue.

Product Description

Laminated Steel padlock PL0028

>Laminated steel in galvanized joint together

>Pin Tumbler Mechanism

>Lever lock mechanism

From Ankey, Stick to top 10 of Laminated steel padlock manufacturer

>Stable Quality

>On time delivery

Material Details

>Laminated steel body

>Harden steel Shackle

>Iron Cylinder or Brass Cylinder

>Iron Keys or Brass Keys

>Iron Latch or Brass Latch

Available Size

>30mm

>40mm

>50mm

>60mm

Customized Function

>Anti-drilling

>Salt Spray testing

>Keyed alike

Notes:

>Production Lead-time is 35-40 days for box package

>The delivery of padlock in blister package is 55-60 days

What's in the package

>One Laminated steel padlock

>2pcs or 3pcs keys

Related

FAQ

Laminated steel body is for superior strength which is not easy to be cut. Each pieces of steel joint tightly by rivet are not easy to be cut.

Of course we can do, it is customized service. You can contact us by email and let us know the details of your requirement.

Firstly, the cost of iron cylinder is cheaper than brass cylinder. Secondly, the appearance of brass cylinder looks better than iron cylinder when grey painting is done. Thirdly, the material of iron is harder than brass, so it will be a case that the keys works on iron cylinder not as smooth as on brass cylinder if some burrs inside of cylinder.

- Nothing meaningful to talk about on theory. Let us put it into actual production, what you can get is: A)80 key differs for 20mm. B) 100 key differs for 25mm. C) 200 key differs for 32mm. D) 600 key differs for 38mm. E)800 key differs for 50mm. F) 1500 key differs fro 63mm.

No difference on the function of security. From the aspect of production process, padlock with pin mechanism can be done by auto-machine now, production capacity gets increased and the precision of padlock is improved.

“Paracentric” or “Universal”, which is most common profile, has the classic rounded “S” shape.

Yes, the laminated steel padlock can be provided with master key system.

Firstly, The manufacturer is top 10 in padlock industry in China. Secondly, Third-part inspection involve in the quality check. Thirdly, our own packing factory double check the quality on each single product before putting into package.

There are two ways we pack keyed alike padlock currently. A) Same key number is packed in one carton. For example, 40mm laminated padlock is 100pcs in a carton, then you get 100pcs same key number from the carton. B) Same key number per package (box or blister), which is min unit for a package, you can do 2pcs in same key number, 4 pcs in same key number or 6 pcs in same key number, but mixed key number for a full carton.